RBD/RDD SERIES (Tube Axial Fans Belt Drive and Direct Drive)

RDD/RBD 12,15,18,21,24,30,36,40,42,48 are all models for tube axial fans that are designed for use in low to medium pressure ducted applications. They are generally used for removal of contaminated air or hot air found in industrial applications; but can also be used to supply air through duct work for cooling or pressurizing of the interior spaces ie. elevator shafts and stairwells for condominiums. Tube axial fans are very versatile and compact for moving large volumes of air in duct systems having relatively low pressure losses.

#1 Axial Fan Manufacturers servicing Canada and USA

Reversomatic axial fan manufacturer have these models to choose from, RBD/RDD 12,15,18,21,24,30,36,40,42,48 are all models for tube axial fans that are designed for use in low to medium pressure ducted applications. Tube axial fans generally used for removal of contaminated air or hot air found in industrial applications; Tube axial fans can also be used to supply air through duct work for cooling or pressurizing of the interior spaces ie. Elevator shafts and stairwells for condominiums. Tube axial fans are very versatile and compact for moving large volumes of air in duct systems having relatively low pressure losses.

Reversomatic tube axial fan manufacturer uses a housing constructed of heavy gauge steel, Airfoil cast aluminum propeller blade, ranging from 800 to 44,000 CFM for RDD tube axial fan and ranging from 1,300 to 70,000 CFM for RBD tube axial fan, tube axial fan static pressure from 0 to 3” SP, motor sizes are ¼ to 50 HP depending on propeller size and CFM desired.

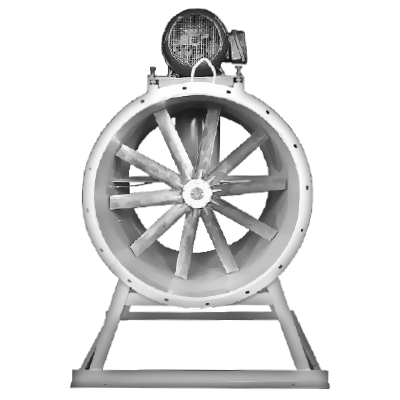

RBD tube axial fan is a Belt Drive fan with motor and drives out of the airstream, All belt-drive tube axial fans supply and/or exhaust are model RBD as manufactured by Reversomatic. Propeller construction consists of extruded aluminum propeller blades mounted in cast aluminum hub. The blade pitch is pre-set at the factory to match design conditions and locked into place by means of a self-locking pin. All tube axial fan propellers are statically and dynamically balanced for vibration-free operation. All tube axial fans have a heavy gauge steel housing and power assembly. All bearings are grease lubricated ball bearing pillow block type with a minimum average life of 100,000 hours. All tube axial fan units have external grease fittings for ease in lubricating. Oil resistant non static belts are provided. All fans bear the AMCA seal for sound and air performance. All steel sheet metal parts are cleaned, conditioned and painted with enamel paint finish prior to assembly. A final coat of gray enamel is applied to all exterior surfaces after assembly.

RDD tube axial fan is a Direct Drive fan with motor in the airstream.

Reversomatic RBD and RDD tube axial fans may be mounted in any position using several different methods, mounting brackets for ceiling suspension and support legs for floor mounting. Angle supports for rod hangers. For convenience in wiring and service, the motor should be readily accessible. On direct drive units, access through adjacent duct work is recommended. On belt drive units, the motor position must be considered with regard to service and adjacent objects such as wall and ceiling. Access door is provided. The duct fan has flanged ends on the steel housing for convenience mounting directly in the duct system. Flexible connections or transition pieces may be utilized to reduce noise transmission, simplify duct attachment and provide access to interior of fan.

A Reversomatic tube axial fan manufacturer has a “B” Running factory standard and optional “A” Running air flow must specify when required.